Reverse Engineering

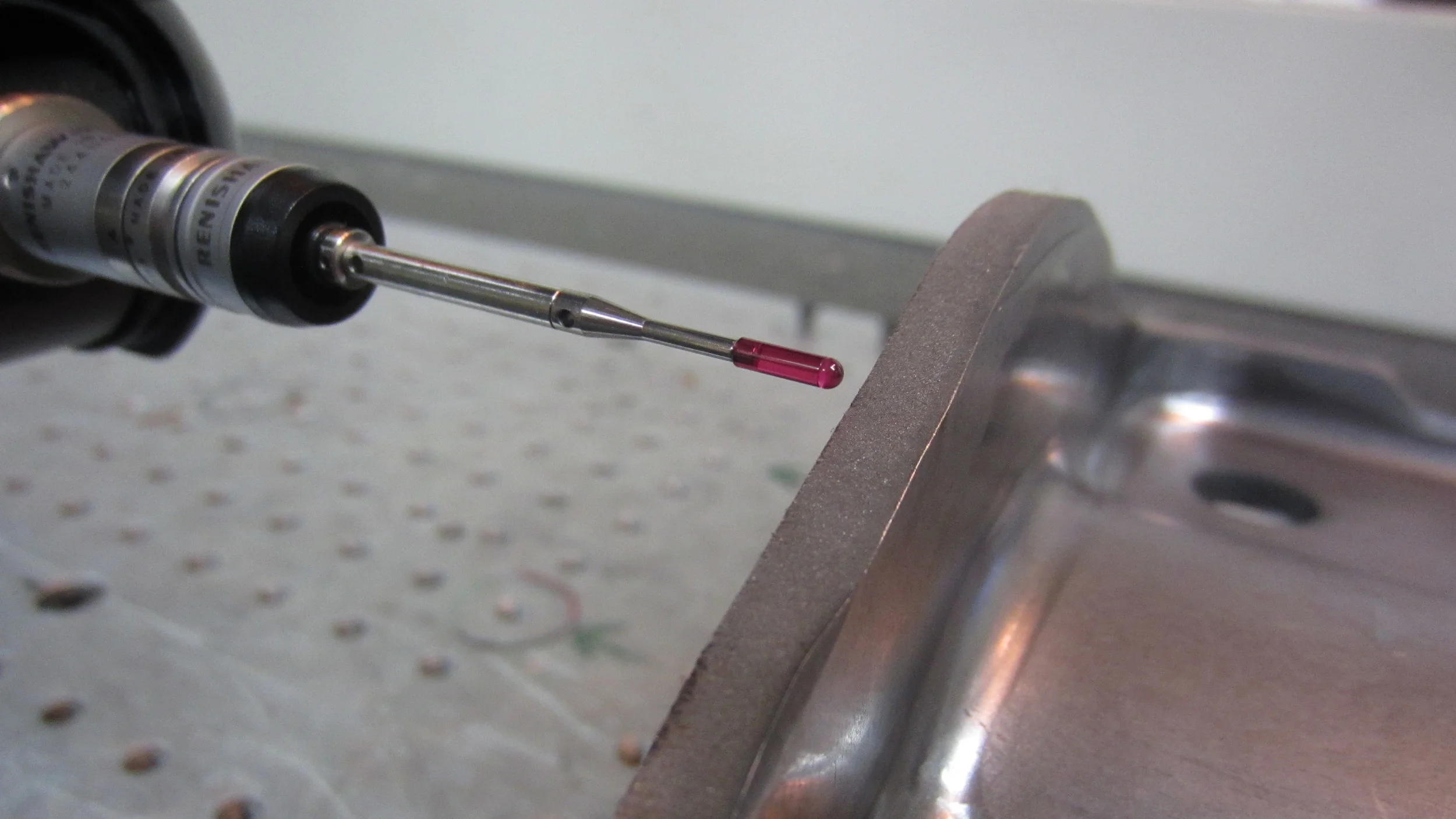

Have a detail with no print or CAD data? No problem, our Quality Department is proficient in reverse engineering details. We use a Sheffield RS50 CMM and a MicroVU M14 Optical Comparator to collect all of the data necessary. This information is sent to our Engineering Department where it is utilized to create a 3D file of the detail. From this we are able to generate a detailed print along with all CAD files necessary to recreate the part.

ISO 9001:2015 Certified

We consider quality of the utmost importance. That is why we have taken the steps to become ISO certified. What this means for our customers is that we adhere to principles and processes that continually point toward ever increasing improvement. We are audited annually to insure that we are following these guidelines. See our ISO certificate here.

QUALITY POLICY STATEMENT

K-K Tool & Design, Inc. will maintain a quality culture based on servicing our customers with quality products that meet or exceed their requirements. We are dedicated to quality products and the provision of the resources and guidance to assure that the quality environment exists.

CMM Part Verification

We 100% validate all parts off of our tooling on our CMM. This includes: a (6) piece layout from the tryout run, a fully ballooned print and roadmap, and a detailed ISIR (Initial Sample Inspection Report).

To contact our Quality Department please email Jade Cale.

Email: quality@kktooldesign.com